Innovations in High Temp Oil Pump Technology: What’s New in 2025

The demand for high-temperature oil pumps has never been greater, with industries like automotive, energy, and manufacturing requiring durable, reliable solutions for their critical operations. But as technology advances, traditional oil pump systems are gradually being replaced by sophisticated innovations that enhance performance, reduce downtime, and improve safety.

2025 marks an exciting turning point for oil pump manufacturers as cutting-edge advancements reshape how businesses harness high-temp oil pump technology. This blog explores the latest innovations revolutionizing the field, highlights their benefits, and provides insights into what the future holds.

Why High Temp Oil Pumps Are Crucial

High-temperature oil pumps—designed to efficiently manage heat and withstand extreme operating conditions—play a key role in industries reliant on thermal oil systems. Whether transferring thermal fluids in manufacturing, supporting industrial heating systems, or enabling petrochemical processing, these pumps are tasked with maintaining consistent performance under demanding conditions.

Traditional pumps face several challenges regarding heat resistance, wear and tear, and energy consumption. This has driven engineers and oil pump manufacturers to develop modern solutions that address these limitations while catering to the growing emphasis on sustainability and energy efficiency.

The Latest Advancements in High Temp Oil Pump Technology

1.Advanced Material Integration

A standout innovation in 2025 is the widespread adoption of advanced materials in high-temp oil pumps. Manufacturers are now utilizing high-performance alloys, ceramics, and composite materials that offer superior heat resistance, durability, and corrosion protection.

For example, pumps with ceramic components can withstand temperatures up to 1000°F (537°C) without compromising integrity, making them ideal for thermal fluid management in industries like chemical processing and food manufacturing. These materials also reduce maintenance needs, saving businesses significant time and resources.

2. Smart Monitoring Systems

Integrating Internet of Things (IoT) technology has transformed how businesses monitor and manage their oil pumps. Modern high-temp oil pumps now come equipped with smart sensors that track critical performance metrics in real-time, such as temperature, pressure, and flow rate.

This data is transmitted to centralized platforms, allowing operators to identify inefficiencies or detect early signs of wear before costly breakdowns occur. Predictive maintenance enabled by these systems minimizes downtime and extends the lifespan of oil pumps.

Key benefits of smart monitoring systems include:

- Early detection of potential failures.

- Increased operational efficiency through real-time adjustments.

- Reduced maintenance costs through precise diagnostics.

3. Energy Efficiency Innovations

With global industries striving to meet stricter sustainability standards, energy-efficient oil pumps have become a top priority. New designs incorporate features like variable speed drives (VSDs) and streamlined flow pathways to reduce energy consumption without sacrificing performance.

Additionally, many high-temp oil pump manufacturers now offer pump systems optimized for renewable thermal fluids, supporting eco-friendly heating processes in industries such as biomass energy and solar thermal power.

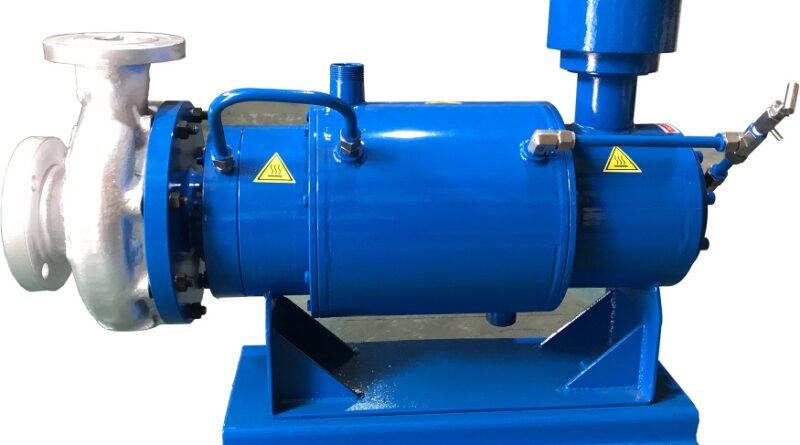

4. Seal-less Magnetic Drive Pumps

One of the most revolutionary advancements in high-temp oil pump technology is the development of seal-less magnetic drive pumps. Unlike traditional pumps that rely on mechanical seals prone to wear and leakage, magnetic drive pumps utilize magnetically coupled components to transfer motion without physical contact.

This innovation eliminates the risk of fluid leaks and greatly enhances operational safety—critical in industries handling hazardous or volatile thermal oils. Furthermore, seal-less pumps are highly durable and require minimal upkeep, making them a cost-effective choice for long-term use.

5. Customized Solutions for Specific Applications

Recognizing that no two industries have the same requirements, leading oil pump manufacturers are increasingly offering tailored solutions. Customization options include modifications to accommodate unique temperature ranges, flow rates, or chemical compatibility requirements.

For instance, manufacturers serving the pharmaceutical sector may design high-temp pumps with specialized coatings that maintain the purity of thermal fluids, while energy companies might opt for pumps designed to handle dense, high-viscosity oils essential for thermal power plants.

This customer-focused approach ensures that businesses can access pump technology that perfectly aligns with their operational needs.

Real-World Applications of High Temp Oil Pumps

The impact of these innovations extends across multiple industries. Here are some applications benefiting from cutting-edge high-temp oil pump technology:

- Automotive: Advanced pumps enable efficient cooling and heat management in engines, ensuring optimal performance and reduced emissions.

- Chemical Processing: Magnetic drive pumps improve safety and reliability when handling hazardous chemicals at elevated temperatures.

- Food and Beverage: Energy-efficient pumps support sustainable food production by lowering energy consumption during heating processes.

- Power Generation: Custom-built pumps for renewable energy systems enhance flow stability and enable compatibility with eco-friendly thermal oils.

- Textile Manufacturing: Thermal oil pumps improve temperature control during dyeing, printing, and other high-temperature processes.

What the Future Holds for High Temp Oil Pumps

As we look ahead, the evolution of high-temp oil pumps shows no signs of slowing down. Emerging trends to watch include:

- AI-Powered Optimization: Artificial intelligence will play a growing role in analyzing pump performance data and delivering actionable insights for even greater efficiency.

- Ultra-Compact Designs: Innovative engineering will lead to the development of space-saving pump systems that maintain high performance in smaller setups.

- Sustainability-Driven Research: Expect to see further investments in eco-friendly materials and renewable energy-compatible pumps to align with global decarbonization goals.

These developments promise to make high-temp oil pumps more accessible, efficient, and sustainable for businesses worldwide.

Choosing the Right Partner for Your High Temp Oil Pump Needs

With so many advancements on the horizon, selecting the right oil pump manufacturer is crucial to capitalizing on these innovations. Look for partners that:

- Demonstrate expertise in designing and developing advanced pump systems.

- Offer customized solutions tailored to your unique requirements.

- Provide cutting-edge smart monitoring and IoT capabilities.

- Have a track record of prioritizing energy efficiency and sustainability.

By aligning with industry leaders, your business will be well-positioned to thrive in the age of innovation.

Harness the Future of High Temp Oil Pumps

High-temp oil pumps are no longer just essential components—they’re strategic tools driving efficiency, safety, and sustainability across industries. With innovations like advanced materials, smart monitoring systems, and seal-less designs, 2025 is shaping up to be a pivotal year in the evolution of this technology.

Is your business ready to take advantage of these advancements? Partner with trusted oil pump manufacturers to integrate the best high-temp oil pump solutions into your operations. Explore how these technologies can revolutionize your industry and propel your business forward.